From analog to digital

The giant Valhall has produced over a billion barrels of oil equivalents since the field was opened in 1982. The ambition is to produce a total of two billion barrels from the area.

Field of the future

Valhall has undergone major changes. It was the first producing field on the Norwegian continental shelf to be supplied with electrical power from shore in 2013. Digitalisation and new technology are key to develop and extend the life of Valhall to produce a total of two billion barrels of oil equivalents within 2060.

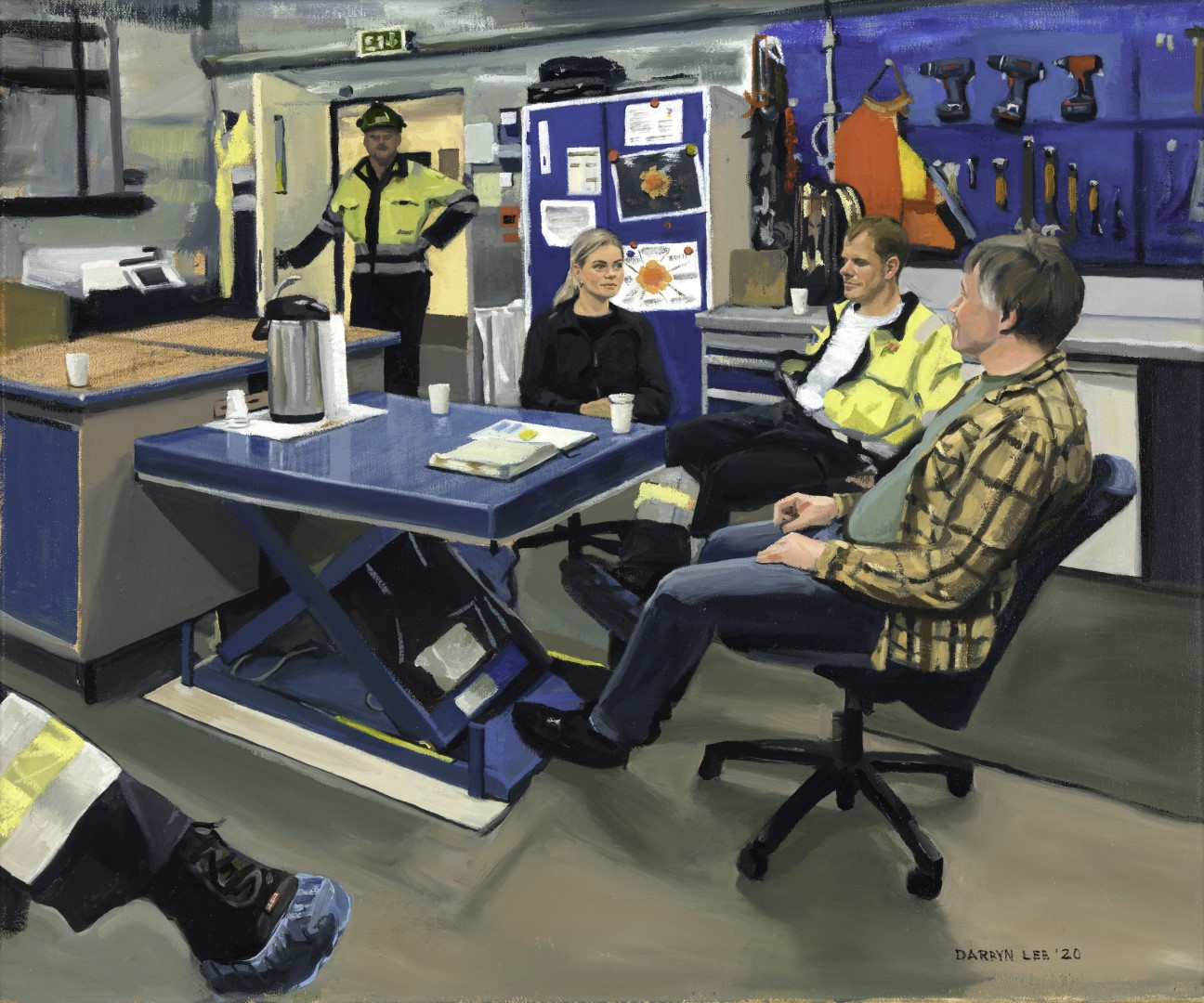

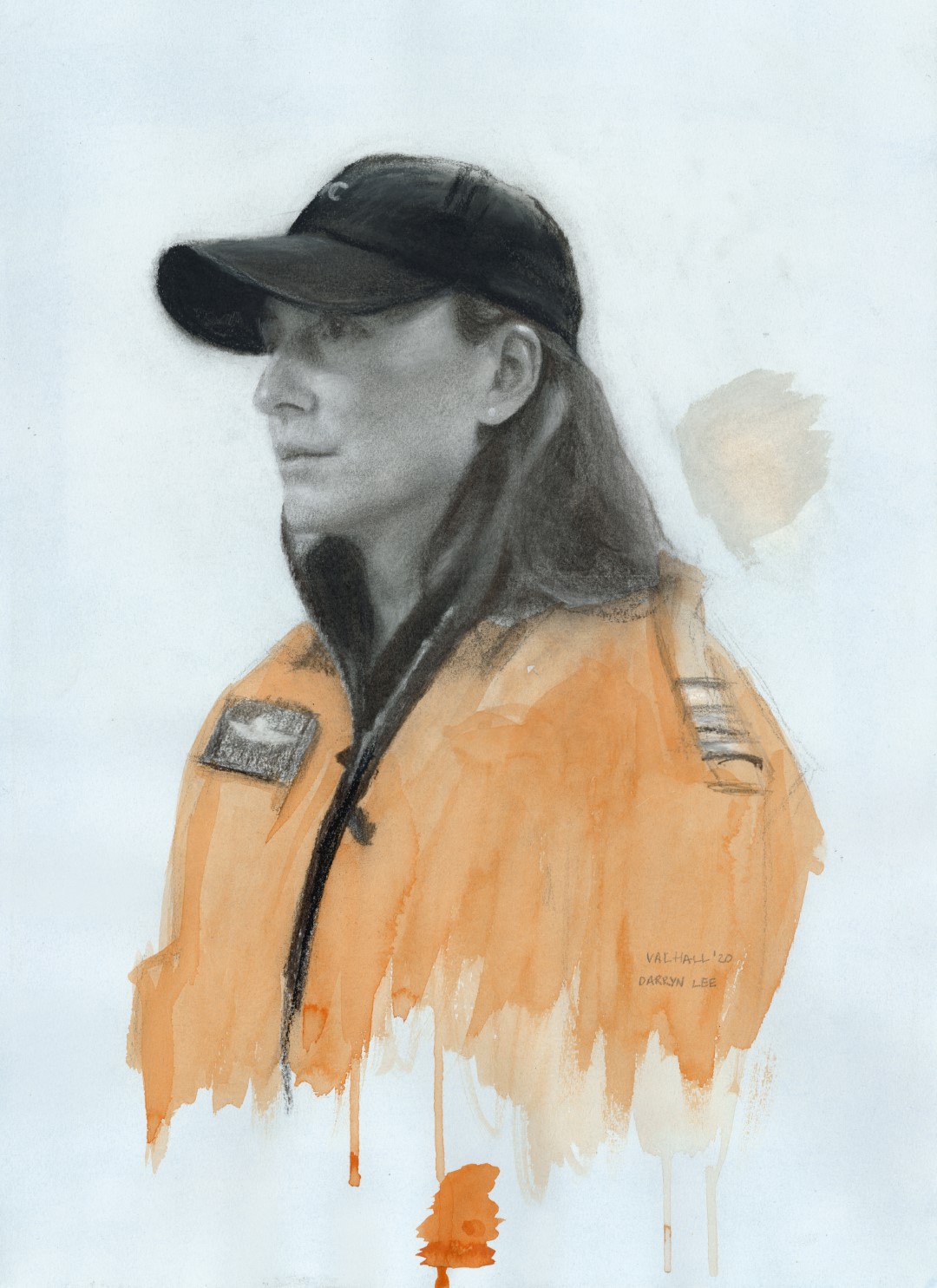

The people

The people are the same. They are developing new competence and adapting to the future production standard.

The team is diverse. Everybody is important. Everybody is included. The working environment offshore is unique. People are working away from home and their families. They are working in shifts, around the clock, and contributing to important income for Norway.

The artist

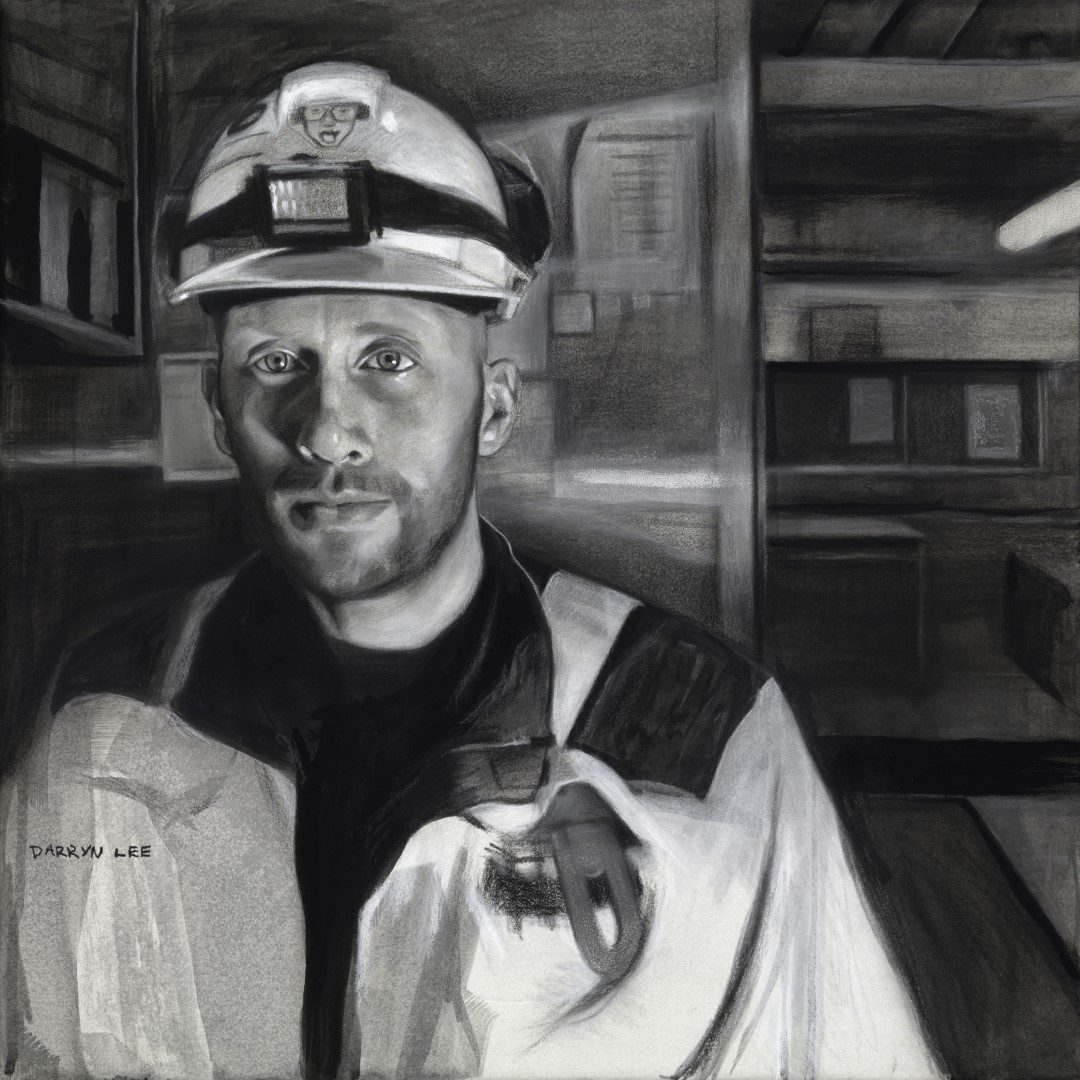

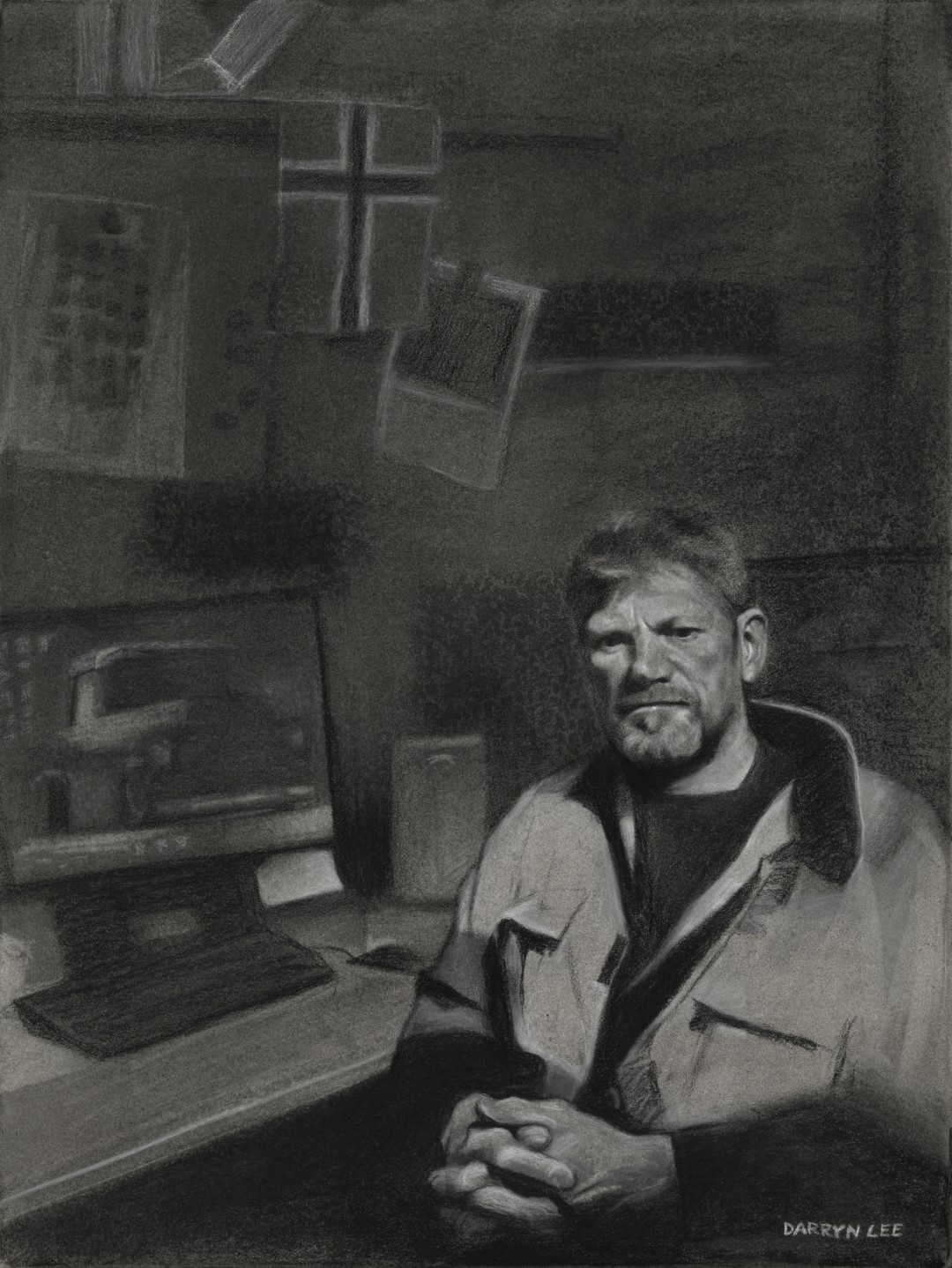

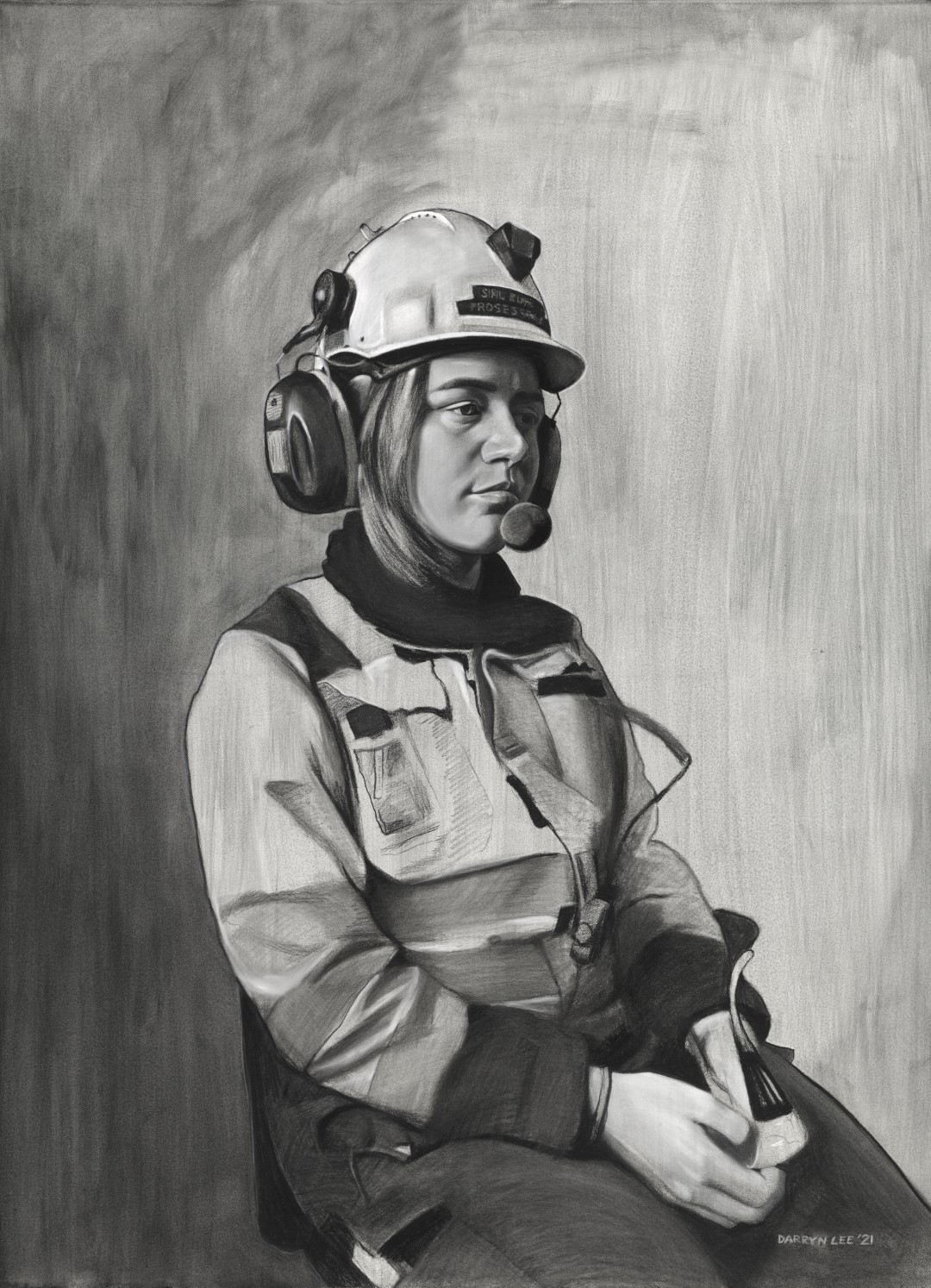

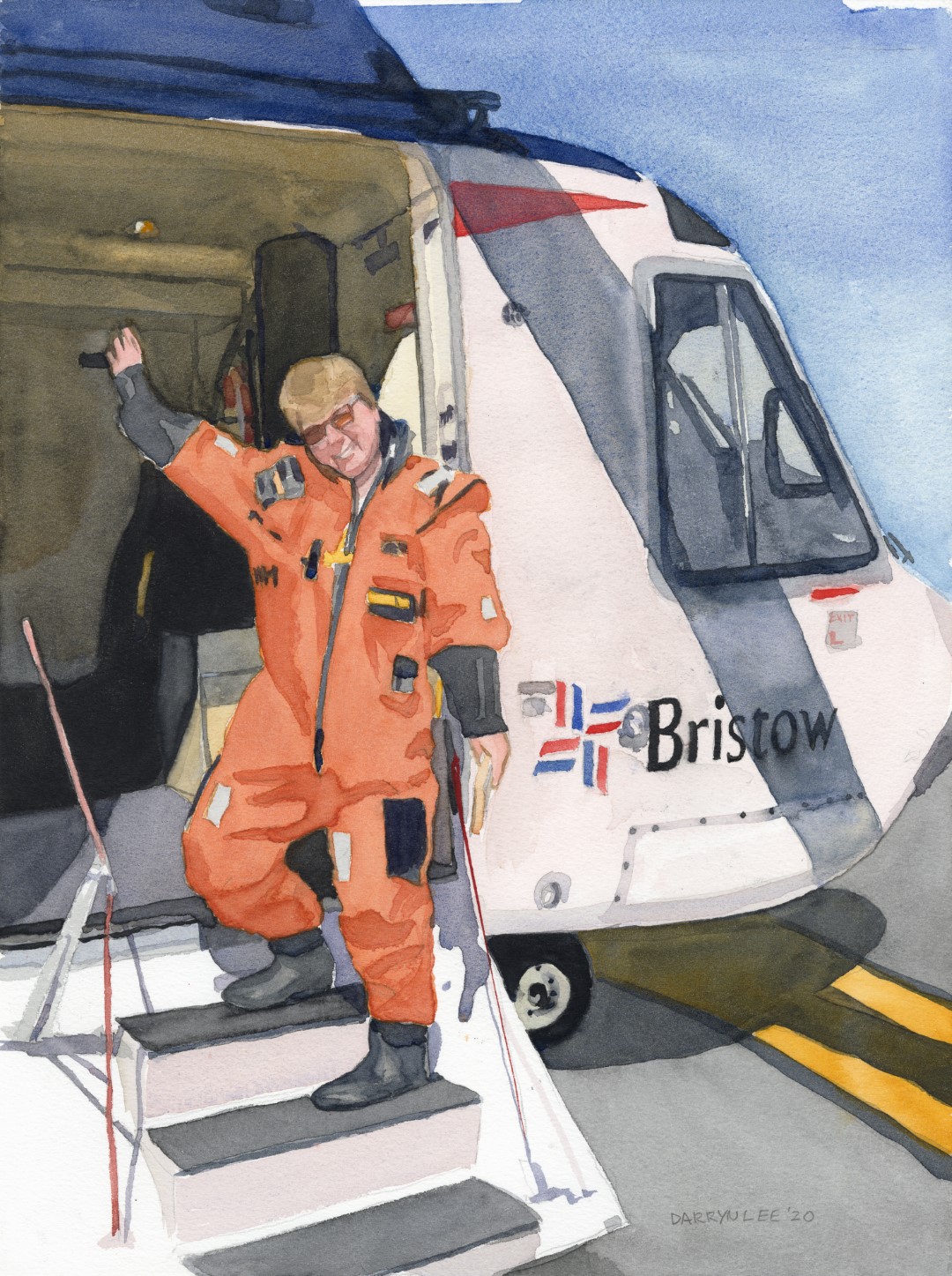

Darryn Lee works with digitalisation on Valhall. He has spent two years documenting the digital transition and the people working on Valhall through the medium of fine art.

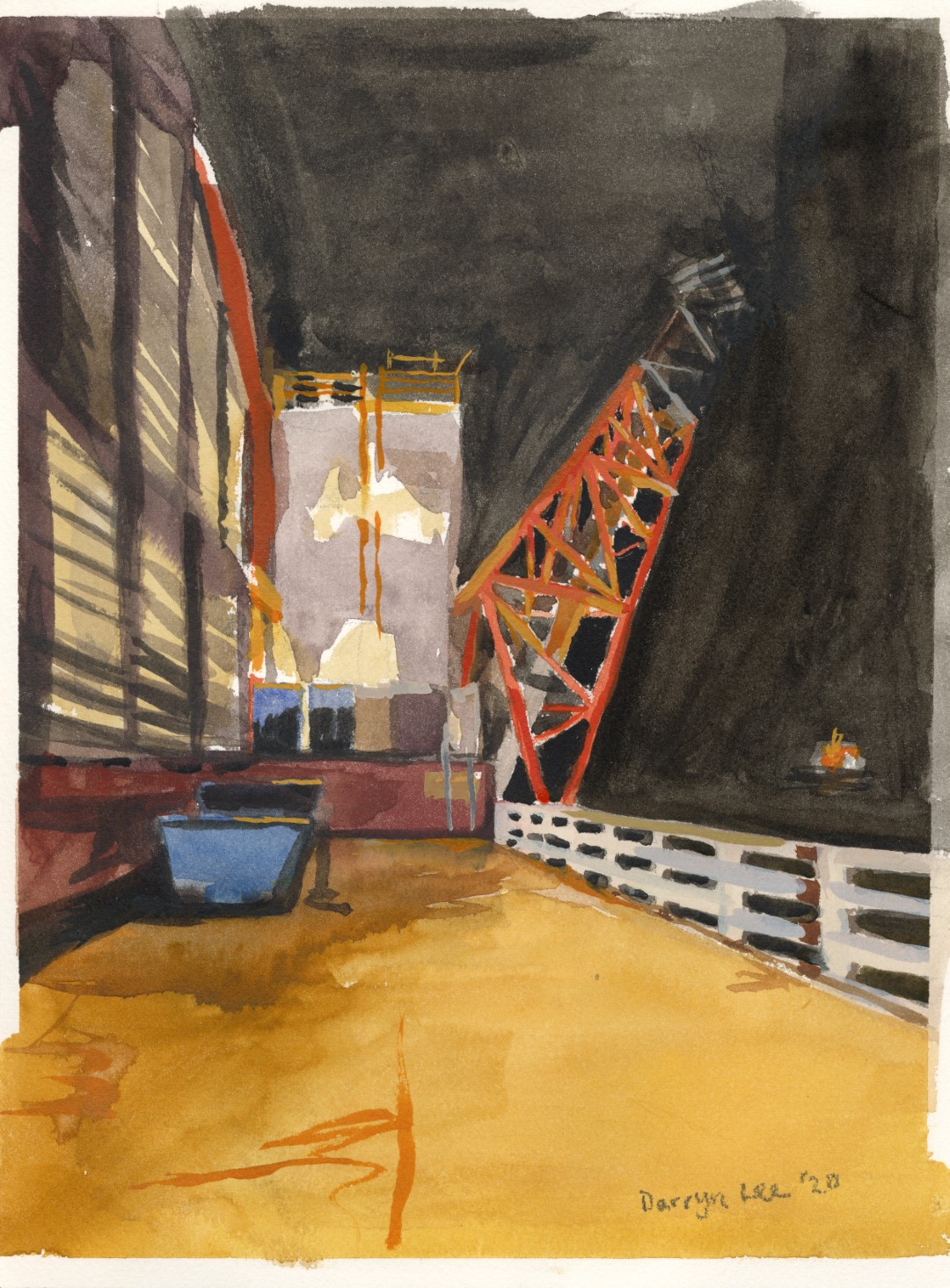

The first part of his work depicts Valhall’s first drilling platform in rust and decay, with a grey sky after 40 years of service. The technology has always required human intervention at every step, however, the old platform now sits redundant. There are portraits of technicians as they come to the end of their working life.

The second part shows Valhall’s modern Production- and Hotel platform with a blue sky, busy offloading the supply boat Orla. Its shiny exterior ready’s itself for 40 more years. First-generation oil workers portraits are replaced by youthful energy and digitalisation.

The steel

The art is mounted on two large steel pipes. This is steel from the Valhall Quarter Platform (QP). The platform was installed at the field center in 1980. In 2020, the top side was removed. In the summer of 2021, the jacket was removed. About 100% of the steel will be recycled. This is high quality steel and attractive in the commodity market. Much is sold to Spain where it is mixed with lower quality steel from household appliances. The end product will be reinforcing steel for the construction industry.

DARRYN LEE

B.1975, Dublin, Ireland

Lives and works in Stavanger, Norway

In his work Analog to digital offshore Darryn Lee uses oil paint, gauche, graphite and various materials. The artist is interested in the transition from analog to digital in an oil company offshore.

This project was fabricated during the ongoing corona epidemic and cultural shift to greener forms of energy production.

https://www.darrynlee.no/darrynlee